RONDCOM CREST FiANA

RONDCOM CREST FiANA is ACCRETECH’s innovative automatic measurement system for inner wall surfaces of ultra-small holes. It is based on RONDCOM CREST, an ultra-high accuracy roundness/cylindrical profile measuring instrument, with the additional features of an ultra-thin non-contact probe and an automatic probe insertion system.

RONDCOM CREST FiANA

Smooth, accurate measurement of the profile and surface texture of inner wall surfaces for ultra-small holes as small as φ0.14 mm

RONDCOM CREST is an ultra-high accuracy roundness/cylindrical profile measuring instrument boasting one of the highest accuracies in the world. One of its major features is the drive and guide method that combines low-vibration drive technology driven by a linear motor, non-contact support technology using air bearings, and a unique positioning mechanism. By adding the extremely high-accuracy positioning of RONDCOM CREST made possible by this method with a φ 0.08 mm non-contact probe and a unique automatic insertion system that accurately guides the probe to measurement points, it is now possible to measure the profile and surface roughness of ultra-small hole inner wall surfaces with a minimum diameter of φ 0.14 mm. RONDCOM Crest FiANA, a state-of-the-art measurement system, accomplishes measurements inside ultra-small holes that people had previously given up on as being difficult and time-consuming.

Automatic probe insertion system enables easy and efficient measurement for anyone

Generally, in order to measure inner wall surfaces of ultra-small holes, the operator must manually operate the measuring instrument and insert the probe for measurement into an extremely small hole. Not only does this operation require high skill and concentration but also entails the risk of the probe impacting with the workpiece and breaking if the insertion position or angle is even slightly misaligned.

RONDCOM CREST FiANA features a unique automatic probe insertion system utilizing camera images to automate workpiece positioning and alignment, as well as probe insertion and measurement. This makes it possible for anyone to easily perform measurements in a short amount of time as well as minimizes the risk of probe breakage.

*The probe position and angle are adjusted manually (approx. once per day), however, adjustments can be made easily by following the guide line display program (patent pending.)

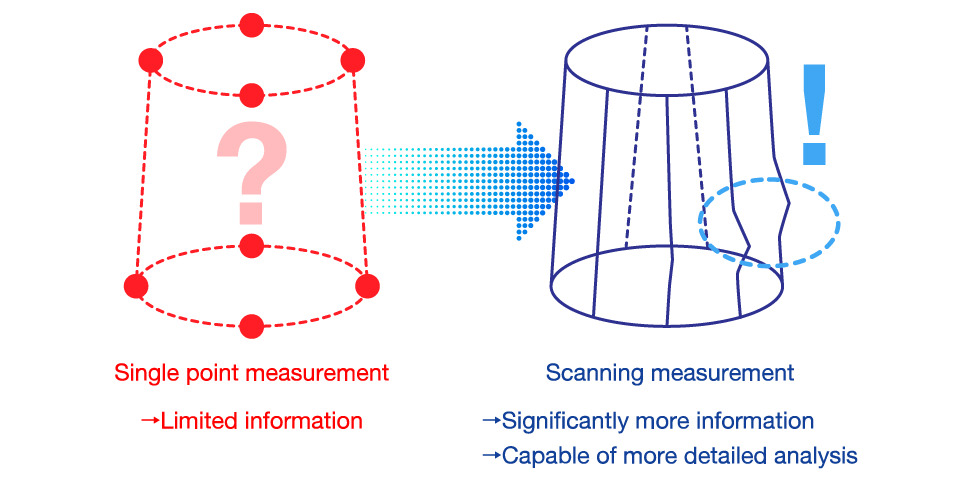

From single point measurement to scanning measurement

Diverse analysis made possible with abundant information

Unlike measurement of large holes able to be measured with a regular roundness and cylindrical profile measuring instrument, inner wall surfaces of ultra-small holes are generally measured at “single point,” but the density of these points is low, meaning only limited information can be obtained, which can make accurate evaluation of the profile difficult. RONDCOM CREST FiANA enables scanning measurement in both the rotating and linear directions, and by combining multiple measured lines enables visualization of the 3D profile of the inner wall.

From single point measurement to scanning measurement. RONDCOM CREST FiANA helps boost our customers’ monozukuri up a rank by the accurate profile measurement of ultra-small hole inner surfaces.

Measurement items

Roundness, cylindricality, straightness (Z), surface texture (rotating and linear directions)

No longer a need for cross-cuts

Nondestructive surface texture measurement that significantly reduces the time and effort required for measurement preparation

To date, in order to evaluate the surface texture of an ultra-small hole’s inner wall, it was necessary to cut the workpiece, expose the inner wall surface, and trace that part using a contact type surface texture measuring instrument. However, with RONDCOM CREST FiANA, which can perform nondestructive measurement of inner walls, such cross-cut preparation is not necessary. By eliminating the entire process of making cross-cuts which not only takes time and effort but also requires skilled machining techniques to accurately cut workpieces in accordance with small holes, measurement preparation time and effort are greatly reduced.