Interviews

A general manufacturer and seller of cold forge tooling performing integrated production from steel material cutting to coating. As a customer of ACCRETECH products supporting high-accuracy die manufacturing, we spoke to Mitsutoyo about their impressions and requests relating to our products.

- MITSUTOYO-KIKO CO., LTD

- Yoshitaka FUNAHASHI, President

- A general manufacturer involved in both the manufacture and sale of cold forge tooling and one of the few companies in Japan to practice integrated production covering everything from material cutting to roughing, heat treatment, polishing, finishing, and coating for practically all types of cold forge tooling. The DoubleHex is a unique six-piece die developed by Mitsutoyo in 1981 and known as the driving force behind the company’s great leap forward. Mitsutoyo-Kiko is a one-of-a-kind company pursuing this kind of originality and high quality.

- Head office: 1-14 Higashinoshinmachi, Kasugai city, Aichi prefecture, 486-0816, Japan

Kagoshima plant: 1542-1 Kiyomizu,Kawanabecho,Minamikyushu city, Kagoshima prefecture, 897-0202,Japan

http://www.mitsutoyo.co.jp/

Please tell us about Mitsutoyo’s unique features.

Funahashi: One unique feature of Mitsutoyo is that we take care of everything from the manufacturing to the sale of cold forge tooling, but another unique feature is the fact that we manufacture a broad range of tooling from that for the large bolts and nuts used in the automotive and construction industries, to tooling for micro screws used in watches, eyeglasses, and computers. Another unique feature is that we proactively convert customers’ needs into tangible products, and a prime example of this is our patented Double Hex which we developed in 1981. This is a product for our customers who voiced they wanted a long-lasting die that doesn’t split easily. It is configured from six isosceles trapezoids. In other words, we developed Double Hex based on the reverse thinking of building it from separate pieces to prevent it splitting during use. This product is so well-known that, even today, long after the patent has expired, people in the industry still refer to similar products as “Double Hex.”

What do you mainly focus on when you consider which measurement equipment to introduce?

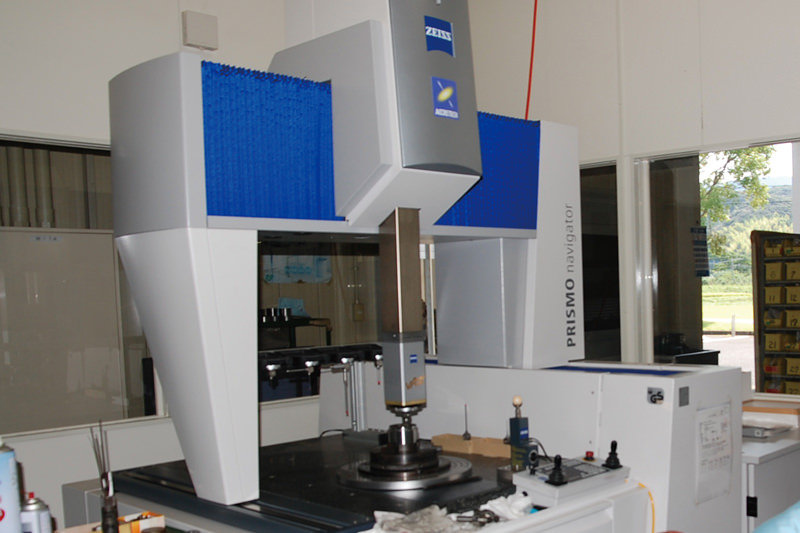

Funahashi: I focus on total cost more than initial cost as evaluation criteria, so even if a measuring machine is slightly more costly, I decide whether or not to purchase it by looking at the level of its functionality, whether it matches our needs, the quality of after-sales support, etc. Another key factor swaying my decision is the quality of communication with the sales representative and how well they know/understand Mitsutoyo. Our relationship with Tokyo Seimitsu dates back almost thirty years and began with us purchasing a shape measuring machine in the form of an XY recorder that draws with a plotter. Today, we have nine shape measuring machines featuring computer analysis functions, as well as the CMMs of PRISMO5, DuraMax, etc.

Please tell us your impressions of using our products

Funahashi: Mitsutoyo’s technical capabilities have improved since introducing measuring equipment for inspection purposes. Back in the days of a pen and drafter, you could even go so far as to say that it was possible to adjust the product to match the drawing. However, in this era of computer analysis, analysis accuracy is extremely high, therefore manufacturers have no alternative but to support that accuracy. Consequently, technology improves organically. Moreover, we align our inspection standards to those of our customers who demand the highest quality, therefore the defective rate has naturally decreased. An unexpected benefit of introducing Tokyo Seimitsu’s measuring equipment to our operations was that, after installing measuring machines in each process where they were needed, our employees’ mindset toward quality changed to one of “I’m going to take ownership over quality myself instead of leaving it up to inspection.” Because die manufacturing work is significantly affected by the motivation of each employee involved, I consider this particular benefit extremely important.

Do you have any further expectations of measuring equipment and Tokyo Seimitsu?

Funahashi: Mitsutoyo manufactures tooling for all kinds of bolts and nuts used in everything from automobiles to computers. Tiny screws such as those for eyeglasses and cell phones can have a hole diameter as small as φ1.0, which makes measurement difficult. Also, considering the current trend of downsizing, it would be great to have equipment enabling us to measure even small objects with high accuracy. I believe a demand exists for this type of measuring. Tokyo Seimitsu is very passionate about caring after us, including after-sales support, but if I could wish for more, it would be wonderful if you could identify what is lacking in our manufacturing operations when you visit to replace or repair your equipment and present proposals responding to such issues. Die manufacturing technology has improved significantly with advancements in machinery. However, there’s also a need for people to pass down technological know-how to the next generation, and I think, as of right now, it is difficult for high-quality products such as ours to be made overseas. I say this because companies based overseas contact us saying “For situations requiring high quality, Mitsutoyo is our go-to manufacturer.” Perhaps they use our products and consider cost-effectiveness. Even though we are more expensive, customers choose us as their preferred manufacturer. In that sense, I think Tokyo Seimitsu’s measuring equipment contributes to our ability to manufacture high-quality products. My belief is that quality is born from the resolve of the person making it and I, along with all of Mitsutoyo’s employees, will continue to increase our motivation as we pursue quality.

Tokyo Seimitsu’s thoughts after speaking

Speaking with Mitsutoyo made us realize the importance of approaching monozukuri from the stance of making sufficient advance investment where necessary in order to create products of an even higher standard and, ultimately, produce high-quality, original products.