Interviews

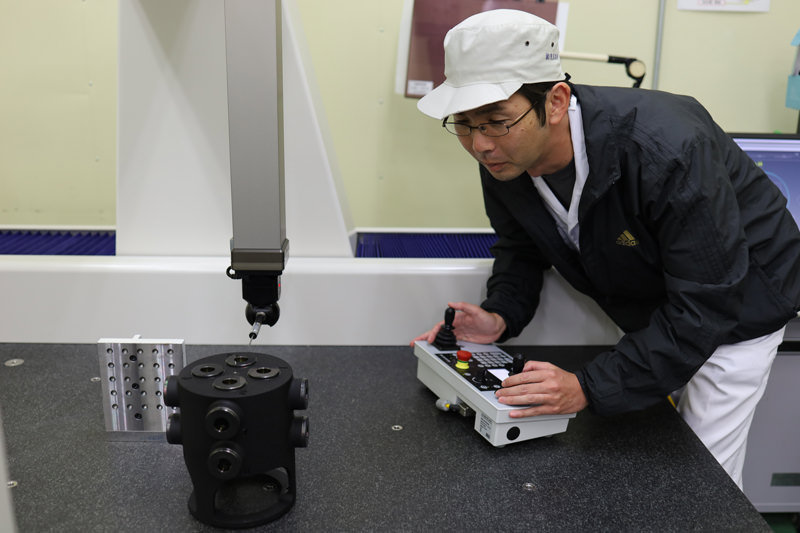

ASANUMA GIKEN manufactures prototypes of industrial machinery parts and fabricates gauges for verification of CMMs. We talked to them about their secret behind personnel training and their unwavering stance of constantly improving accuracy.

- ASANUMA GIKEN CO., LTD

- Susumu ASANUMA, President

- Founded in 1977, Asanuma Giken is primarily involved in manufacturing of prototypes for automotive and industrial machinery parts, precision aluminum sand casting, manufacture and sale gauges for verification of CMMs, performing measurement work upon request, and block gauge calibration. Furthermore, in addition to being NVLAP certified by N.I.S.T (National Institute of Standards and Technology) and certified by the Minister of International Trade and Industry based on the JCSS Measurement Law, Asanuma Giken is actively refining its technical capabilities, such as the development of a mold-sand hybrid mold, which is an innovative casting technology.

- Head office and No.1 Plant: 4079-1 Kotoucho Nishi ward, Hamamatsu city, Shizuoka prefecture, 431-1103, Japan

No.2 Plant: 5948-1 Kotoucho Nishi ward, Hamamatsu city, Shizuoka prefecture, 431-1103, Japan

http://www.asanuma-g.jp/index.html

Please tell us about Asanuma Giken.

With the aim of world-class monozukuri, we have adopted an integrated system for materials, processing, and measurement. These are collectively referred to as "Monozukuri Restoration" and meet the needs of customers to realize the best total benefits by (1) striving to realize high quality, (2) proposing total cost reduction, and (3) responding to short delivery times. Our primary business is prototyping of transportation equipment parts. Rather than focusing on prototyping alone, we thought about developing our own products, and after 10 years of research, developed Quality Master as a gauge for verifying CMMs. We were certified by the National Institute of Standards and Technology (N.I.S.T) with NVLAP (LAB CODE:200536-0) as a calibrator of this product and Quality Master is also recognized as a calibrated product by the National Metrology Institute of Germany (PTB). We also expect to acquire NVLAP certification from NIST for new aluminum alloy. In Japan, we have obtained National Certification (JCSS) as a block gauge calibration company based on length. We are currently enjoying our work with the aim of further expanding sales in the world of our products.

What approach do you take to training?

As president, I think it's important to trust in, and be trusted by, my employees. That is why I tell them about our company’s general policies, etc., but basically, I put my faith in them and entrust them with a great many tasks. My workers are doing very well in line with our policies. Also, my motto is “to be kept alive by others.” Just as this expression implies, I feel that I am being given the opportunity to have freedom of thought because my employees work so hard; in other words, I am living my life while asking a lot of my employees and family. In order to connect the company, it is necessary to respond to different ways of thinking due to changes in the times. Therefore, I think that it is important to consider every aspect from my employees’ point of view and to make our company one where employees feel at ease. Even if the company's is not currently producing much of a profit, by investing in training and nurturing personnel, we can envision a bright future. Recently, I have used the company's funds to have employees attend university and earn their doctorate. In addition, our section chiefs, group leaders, etc. get together once a month to share information on profit, etc. and discuss issues. Then, after grasping the current situation realistically, I make each person think about what to do. This strategy has worked, and everyone's way of thinking has changed a lot. With this approach, I think we need to make our company even more interesting.

Please tell us any points you don’t compromise on when it comes to your operations.

Above all else, we pursue accuracy. That is why, when choosing a measuring machine, price is not a deterrent as long as the accuracy is good, and we even design our building to have a high ceiling and be window-free in order to maintain room temperature for the sake of equipment. We are also very particular about casting materials. For example, sand. It's expensive, but we use artificial sand instead of natural sand. This is because, compared to the uneven grains of natural sand, the artificial sand is uniform with beautiful round grains, so the way it accumulates at casting is different. In addition to this, even if a material has the same name, its characteristics may vary depending on the country it is made and the manufacturer. Even if there is a slight difference, the result of the casting depends greatly. As such, we measure the content and strength of the materials in our laboratory and examine the differences. We are also willing to invest in materials that can be made with higher accuracy to improve the quality of our products. By conducting research in this way, we provide solutions that other companies cannot and products that customers do not yet have. For this reason, many customers turn to us to consult about differences in product quality, so we evaluate the differences after measuring a certain material, and offer guidance on what direction can be taken.

Please tell us any future goals you may have.

Our future goal is to become a company that can compete on a global stage. I would like to expand out from Japan in the future to the U.S., Germany and other European countries, and eventually Southeast Asia. As such, I am meticulous about investing generously in the production of higher-accuracy products as well as the equipment and professionals that create them. ACCRETECH’s "XENOS” is one of such investment. It was quite expensive, but premium products conceived through efforts such as these are essential for us to compete in the world, and I think we can be victorious in the end. There is no point if we don’t succeed, so I want to create products that will be certain winners.

Tokyo Seimitsu’s thoughts after speaking

In order to create products with higher accuracy, Asanuma Giken exerts great effort, day in and day out, and is sticking strongly to its beliefs in regards to not only measuring machines but also people, equipment, and materials. Because of their strong commitment, Asanuma Giken has won numerous awards related to manufacturing. We feel that the attitude of constantly conducting research not only in Japan but also with a view to the world led to the company’s advancement and evolution to date. ACCRETECH will continue to engage in product development so that we can contribute to Asanuma Giken’s creation of products with even higher accuracy.